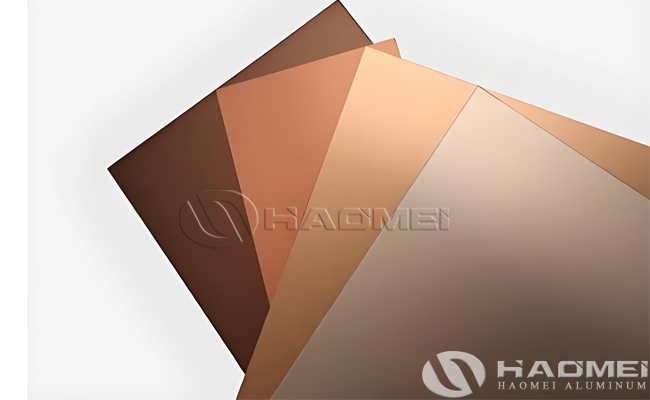

Rose gold anodized aluminum sheet is a high-end decorative material made by coloring a high-purity aluminum substrate through a precision anodizing electrolytic process. Aluminum alloys such as 6063, 5052 and other grades is used as the substrate, which has the characteristics of light weight (density of about 2.7g/cm³), moderate strength and good corrosion resistance. The rose gold color formed on its surface is not an ordinary coating, but a permanent embedding of metal ions in the oxide film that grows naturally on the aluminum substrate through an electrolytic reaction, presenting a luxurious and stable champagne pink gold texture. This process not only gives it a unique visual charm, but also integrates the cutting-edge performance advantages of anodized aluminum, becoming a revolutionary material in the field of architecture and design.

Core advantages of rose gold anodized aluminum sheet:

– Eternal color, resistant to fading and corrosion

Rose gold is solidified in the oxide film through microporous coloring and sealing technology, with excellent UV resistance, and will not change color for 20 years of outdoor use. The oxide film thickness of anodized aluminum sheet can reach 10μm (outdoor grade), isolating acid rain and salt spray erosion, and has passed the 3,000-hour neutral salt spray test, far exceeding the surface sprayed aluminum sheet.

– Self-repairing and anti-fouling, maintenance cost is close to zero

The surface oxide film has a honeycomb microcrystalline structure, which is difficult for stains to penetrate. Daily cleaning only requires wiping with clean water, leaving no fingerprints or water marks. If there is a slight scratch, the gel substance in the oxide film can automatically migrate to repair the scratch and maintain integrity.

– Safe and environmentally friendly, exceeding fire protection standards

No paint is added, the substrate and the oxide layer are both inorganic, the fire resistance temperature reaches 600℃ (ASTM E84 test), and no toxic gas is released when encountering fire, meeting Class A fire protection requirements, suitable for high-standard places such as airports and hospitals.

– Light, tough and strong combination, double processing efficiency

The hardness reaches sapphire level (Mohs level 9), and the scratch resistance is excellent, while maintaining the lightweight nature of aluminum (density 2.7g/cm³). Support high-speed stamping, bending, CNC engraving and other processing, the yield rate is increased by 30%, and the delivery cycle is greatly shortened.

Application scenarios of rose gold anodized aluminum sheet:

– Architectural landmarks: super-high-rise curtain walls, luxury store facades, rose gold tones present gradient light and shadow under sunlight, enhancing the recognition of buildings.

– Refined interiors: elevator cars, artistic partitions, customized furniture panels, metal textures and warm tones create a luxurious atmosphere.

– Technology products: high-end electrical panels (refrigerators, heaters), electronic equipment shells, integrating protection and consumer aesthetic upgrade needs.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form